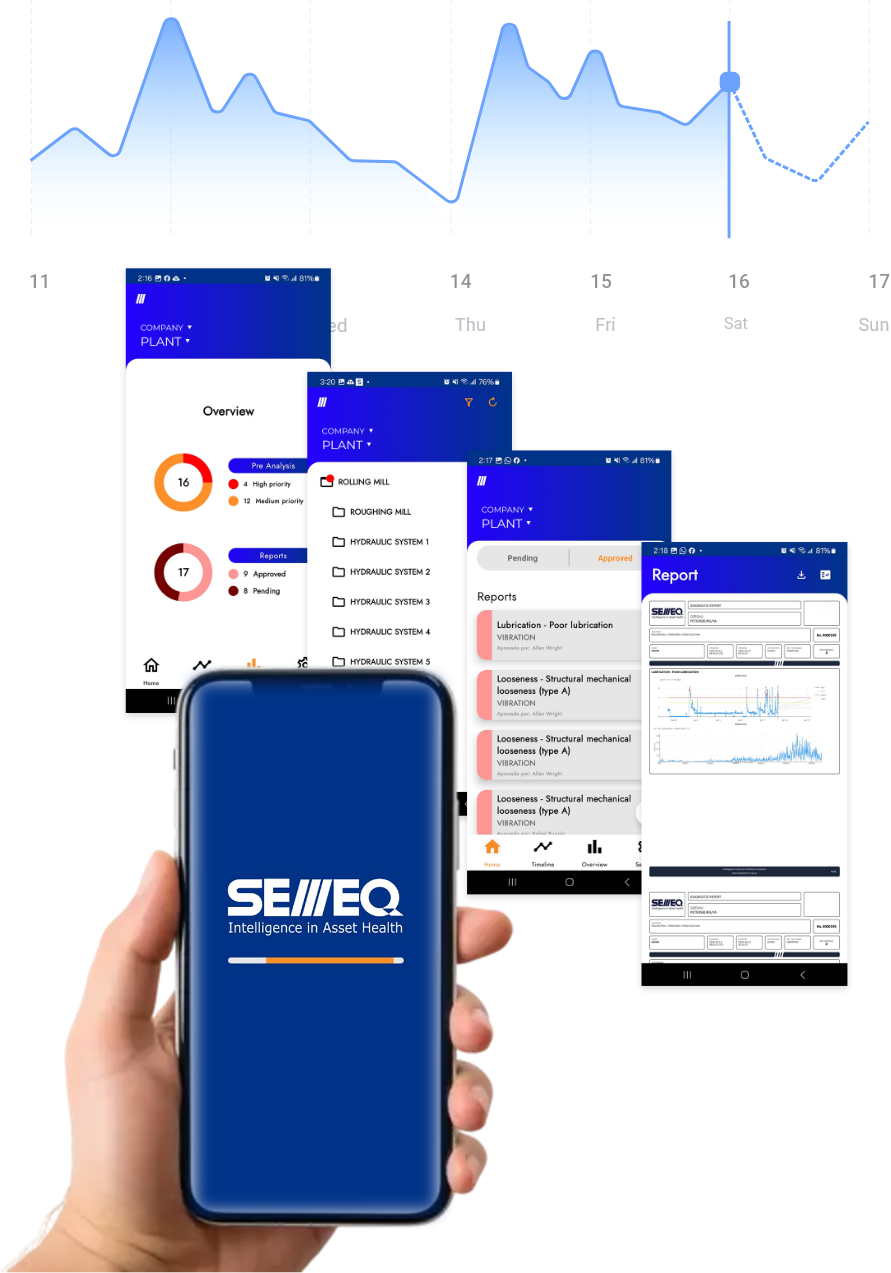

Converting data and information to business value.

Semeq provides a complete package of solutions to streamline the implementation of your projects. We offer a wide range of sensors and integration tools that capture information and connect it with our experts via Artificial Intelligence (AI). We also have a whole team of inspectors and system integrators who work full or part-time at your plant to collect data, samples, images, and process variables. Click below and check it out!