Sensor

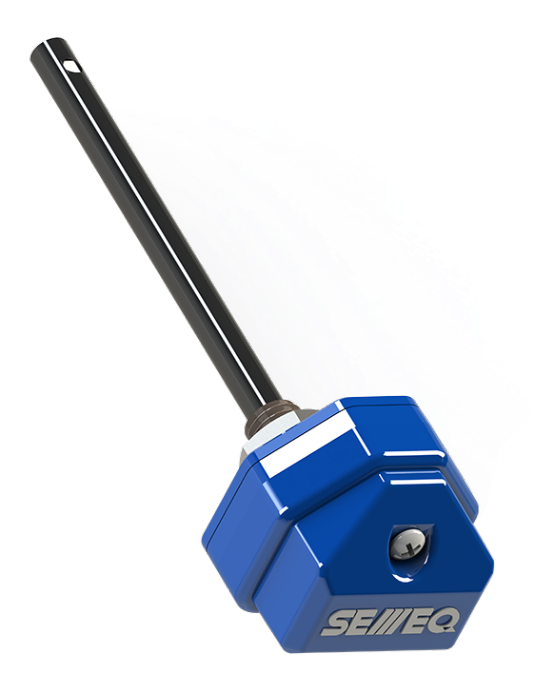

SensorHumidity and Temperature Sensor

Sensor for predictive maintenance for critical assets

Humidity and Temperature Sensor

FEATURES:

- High accuracy temperature measurement.

- Relative air humidity measurement

- Wireless communication via Bluetooth® Low Energy 5.1 – (BLE 5.1)

- Long-life battery duration and replaceable

- IOT Device

- Protection Rating: IP 69

APPLICATIONS:

- Monitoring of temperature and relative humidity of electrical control panel

Safety

It eliminates the need for routine employee inspections to check temperature and humidity, prevents the opening of energized panels, and reduces the risk of short circuits and accidents.

Two in One

Provides measurement of two essential quantities, temperature and humidity, with a single sensor, optimizing resources and simplifying installation and maintenance. SEMEQ’s humidity and temperature sensor improves operational safety and offers efficiency and practicality by monitoring two critical variables simultaneously.

Request a demo

We offer your company broad and secure forms of data storage.

Click to find out more about this service