We are thrilled to announce a game-changing collaboration redefining Laser Shaft Alignment in the southern United States.

SEMEQ SYSTEMS and HAMAR LASER, renowned for their top-notch products like the X-Series™ Laser Shaft Alignment, have joined forces. As authorized distributors of Hamar Laser in Texas, Oklahoma, Louisiana, Arkansas, Missouri, and Iowa states, we are excited to bring you the best-in-class X-Series™ Laser Shaft Alignment products, known for their unwavering reliability and performance.

Our quest to expand and capture market share in the region led us to seek a partner who shares our vision for innovation and brings unique strengths and expertise; we found the ideal match – a company with a diverse clientele and a proven history of delivering exceptional solutions in HAMAR LASER.

About HAMAR

For over 55 years, Hamar Laser Instruments has pioneered laser alignment, with 34 years dedicated to shaft alignment applications. The company aims to enhance asset availability, drive customers’ profitability, and reduce operational costs. Hamar Laser is committed to innovation and clients’ success and delivers cutting-edge solutions that empower customers to thrive.

X-SERIES PRODUCTS

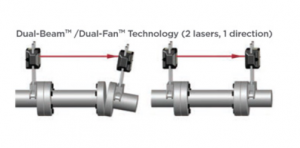

Discover the Innovation Behind Unidirectional Dual-Beam™ and Dual-Fan™ Technology

The X-Series™ Laser Shaft Alignment products are designed with your ease of use in mind. Our Hamar software has undergone rigorous development to ensure user-friendliness, requiring minimal training even for complex applications. We aim for simplicity that instills confidence and comfort in our users, making the technology feel like second nature.

Safety Features in the X-Series™

The X-Series™ is designed with your safety in mind, and it incorporates multiple safety features, including rugged IP65 Windows® tablets and IP67 laser heads and targets suitable for harsh environments. Bluetooth® technology enables wireless communication between the tablet, laser, and target, enhancing safety around rotating equipment. Small-diameter laser beams and narrow-line laser fans maximize the PSD sensor measuring range, enhancing safety compared to competitors’ more comprehensive laser lines. With these safety features, you can feel confident and secure about the operation of the X-Series™.

Advantages of Laser Alignment Systems Over Indicators

The X-Series™ Laser Shaft Alignment products offer advantages over traditional methods like dial indicators. Determining the rotation axis of one shaft relative to another in shaft alignment is crucial for eliminating misalignment. Conventional methods could be more convenient, precise, and time-consuming, requiring interpolation of readings, compensation for bracket sag, and manual calculations, complicating the process. The X-Series™ Lasers streamline alignment by recording position and angular data using the software while rotating the laser and target, capturing up to 16 points/second. This method calculates and subtracts mounting errors from the raw data, providing highly accurate alignment without manual calculations and offering a hassle-free experience.

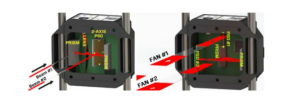

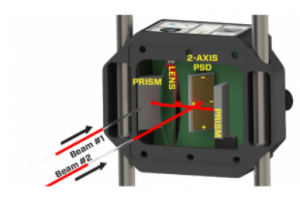

Unlocking Enhanced Precision and Flexibility with Dual-Beam™ Detector Technology

Our patented Dual-Beam™ technology is a game-changer in laser alignment systems. It allows for simultaneous measurement of offset and angle with just one PSD, boosting system accuracy by an impressive 50%. We conduct a meticulous 500-point calibration on the PSD, setting a new industry standard for accuracy that surpasses competitors’ systems by up to 15 times. With this level of precision and accuracy, you can trust the performance of our Dual-Beam™ technology.

But the innovation continues beyond there. With Dual-Beam™ technology, you gain an extraordinary angular range of +/- 12 degrees, ensuring consistent laser targeting even in long-distance applications. Plus, our angular resolution surpasses the highest angular tolerance by a factor of 10, guaranteeing unmatched precision in alignment processes.

Our blinking laser technology seamlessly compensates for ambient light variations to elevate performance further, ensuring reliable measurements regardless of environmental conditions.

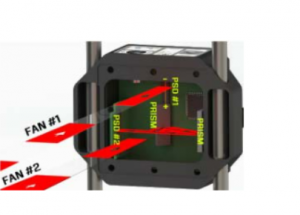

Outperforming Competitor’s Mid-Range Systems: Introducing Entry-Level Dual-Fan™ Detector Technology

Our Dual-Fan™ technology redefines entry-level shaft alignment systems, delivering unmatched economy, versatility, and accuracy. With Dual-Fan™, you can achieve exact measurements of offset and angularity simultaneously, thanks to two 0.5-degree laser fans and two 20 mm PSDs.

Unlike competitors’ lasers, which pose safety concerns with wider fan spreads, our specially designed laser fan extends only to 1 inch (25.4 mm) at 15 feet (4.6 m), ensuring safer operation without compromising accuracy.

Moreover, Dual-Fan™ offers a full angular measuring range across the entire operating distance between the laser and the target. This eliminates the limitations of the “cross-fire” lasers face, which experience restricted angular measuring ranges beyond 3 feet (and 1 m). Conducts a meticulous 40-point calibration procedure on the P to further enhance accuracy, making our Dual-Fan™ technology up to 5 times more precise than competing mid-priced systems. Blinking laser-fan technology also compensates for ambient light, guaranteeing consistent environmental performance.

Durable, Sealed IP67 Casings

All X-Series™ alignment hardware “heads” are compact, sturdy, and engineered to swiftly and effortlessly deliver precise, reliable alignment data. They boast an IP67 rating for waterproofing (submersible up to 3 feet or 1 meter), ensuring durability in harsh conditions. Our handheld display units feature high-resolution, color touchscreens. Unlike competitors, our wireless transmitter is securely enclosed within the heads, eliminating the risk of connector or cable failure.

Embedded Technology

We prioritized user-friendly design, integrating “smart” LEDs for intuitive laser status indication at a glance.

Intuitive Software for Seamless Alignment

Our Couple6 software is as intelligent as our hardware, featuring Easy-Guide™ navigation with vibrant color screens that guide users effortlessly through each alignment step. Even beginners can achieve expert-level results with our 5-step process, culminating in easy report generation.

Revolutionary Live Move Screen for Precision Shaft Alignment

Introducing Duo-Plane™ Live Move screen, an innovative feature on the T-1290 5-Axis Target. Unlike traditional systems, Duo-Plane™ allows users to view vertical and horizontal alignment screens simultaneously, eliminating the need to rotate shafts. This groundbreaking technology saves valuable time, particularly on large machine applications where bolt tightening can cause machine movement, necessitating realignment.

In our X-660 and X-770 3-axis systems, we introduce an intuitive 2-axis “live” display feature. This dynamic display showcases continuously updating graphics, clearly illustrating motor alignment along the horizontal or vertical axis. Simply rotate the shafts from 12:00 to 3:00 or 9:00 to activate the horizontal axis live move screen. The Couple6 system seamlessly transitions to display alignment results, allowing you to adjust the motor position without the need to reacquire data.

Effortless Precision with Extended PSD Measuring Area

Experience the convenience of our large 20-33 mm PSD measuring areas integrated into our target heads. Coupled with our uni-directional laser beams and an impressive +/- 8 to +/-12 degrees of angular range, you can bypass the time-consuming “rough” alignment process typically required during new machine installations. This translates to significant savings in labor hours each month! Simply attach the laser and target to the shafts and proceed to our Step 2 Laser Setup Screen, where you’ll find a live display of the angular alignment. Rotate the shafts, and you’re ready to capture data if you achieve readings for at least 90 degrees. If not, utilize the live display to roughly align the motor angle for data collection. It’s that straightforward!

Instant Support with On-Demand Training Resources

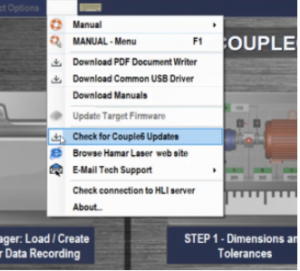

Always feel safe again with our comprehensive training resources available at your fingertips. Access our electronic manual directly within our Couple6 software by selecting the Help Menu or hitting F1. The correct page of the manual will automatically display, providing quick assistance whenever needed. Watch our on-demand training videos for a quick recap of any procedure. Compare this seamless support experience to our competitors’ cumbersome multi-page cheat sheets or lengthy manuals. With our intuitive software, training is primarily needed for more complex applications, ensuring efficient and hassle-free operation.

No Worries with Off-the-Shelf Software Display

With the X Series, you get the convenience of Windows 10 IoT Enterprise IP65 rugged tablets, available at most computer stores. Say goodbye to costly, proprietary display devices – if your tablet breaks, replacements are easily sourced.

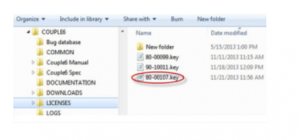

Seamless Upgrade to Advanced Features

Upgrade your entry-level laser system to unlock advanced features effortlessly. Simply send your distributor or us a purchase order for the desired features, and within a day, you will receive a new license via email. Installation takes seconds, and voilà – the new features are ready to use in our Couple6 software!

Printing Reports Made Simple

With our tablets and PCs, printing detailed, customizable color reports is a breeze. Just plug the report into a printer and hit print. Need to email a report? No sweat! Select PDF in the print screen, attach the report to your email, and send it off. Easy as pie!

Continuous Software Updates at No Cost

We believe in constantly enhancing our software to serve our customers better. That’s why we provide free updates for life. With just a click on “Check for Updates,” Couple6 takes care of the rest.

The Advantage of Unidirectional Dual-Beam™ and Dual-Fan™ Technology for Long Spans

Long-distance applications pose challenges for traditional 2-laser/2-detector shaft systems. Even tiny angular movements can significantly affect readings, making alignment difficult, especially for the horizontal axis. Our uni-directional laser technology eliminates this problem. Unlike traditional systems, angular moves to the motor don’t impact the laser beam or offset values. This makes motor alignment remarkably easy, particularly over long distances.